Check valves are an essential component in many industrial processes, and their replacement can be a significant expense. The cost of a new check valve can vary widely, depending on several factors such as the type, size, and material of the valve. In this article, we will explore the different types of check valves, their characteristics, and the factors that affect their cost.

Types of Check Valves

There are several types of check valves available, each with its unique characteristics and applications. The most common types of check valves are:

Swing Check Valve: This is the most common type of check valve, which uses a swinging disc to block the flow of fluid. Swing check valves are relatively inexpensive and easy to maintain.

Lift Check Valve: This type of check valve uses a lift to block the flow of fluid. Lift check valves are often used in high-pressure applications and are more expensive than swing check valves.

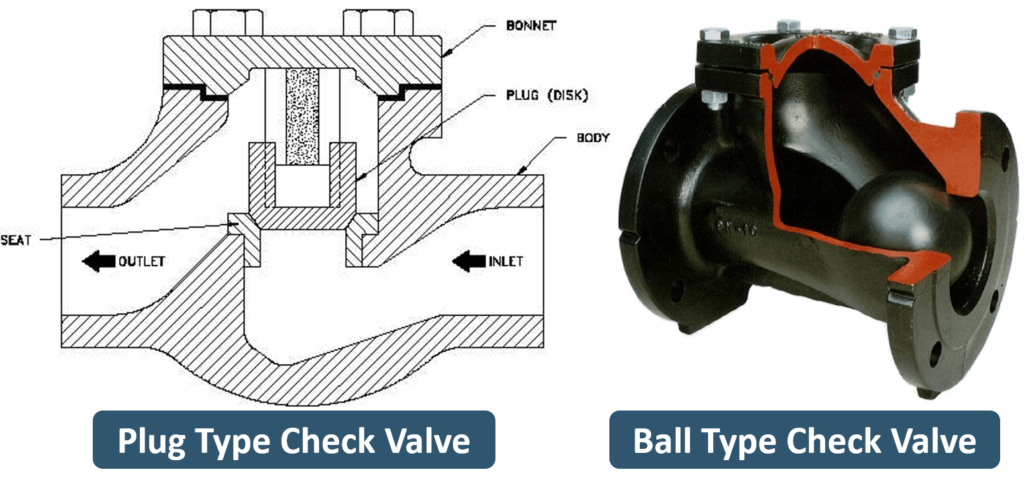

Ball Check Valve: This type of check valve uses a ball to block the flow of fluid. Ball check valves are compact and lightweight, making them ideal for use in small spaces.

Diaphragm Check Valve: This type of check valve uses a diaphragm to block the flow of fluid. Diaphragm check valves are often used in applications where high pressure and temperature are present.

Factors Affecting the Cost of a New Check Valve

The cost of a new check valve can be affected by several factors, including:

Material: The material used to manufacture the check valve can significantly affect its cost. Check valves made from high-quality materials such as stainless steel or brass are more expensive than those made from lower-quality materials.

Size: The size of the check valve also affects its cost. Larger check valves require more material and are more expensive to manufacture.

Type: The type of check valve also affects its cost. Lift check valves and diaphragm check valves are more expensive than swing check valves and ball check valves.

Brand: The brand of the check valve can also affect its cost. Reputable brands often charge more for their products due to their reputation for quality and reliability.

Supplier: The supplier of the check valve can also affect its cost. Authorized distributors may charge more for their products due to their relationship with the manufacturer.

How to Reduce the Cost of a New Check Valve

While the cost of a new check valve can be significant, there are several ways to reduce the expense. Here are some tips to help you save money:

Shop Around: Comparing prices from different suppliers can help you find the best deal. Be sure to compare prices from authorized distributors, as they may offer better deals than unauthorized suppliers.

Consider Used or Refurbished Check Valves: Used or refurbished check valves can be a cost-effective alternative to new check valves. Be sure to inspect the valve thoroughly before purchasing and ensure that it meets your requirements.

Look for Discounts and Promotions: Keep an eye out for discounts and promotions offered by suppliers. You can also sign up for newsletters and follow suppliers on social media to stay informed about upcoming deals.

Consider a Different Type of Check Valve: Depending on your application, you may be able to use a different type of check valve that is less expensive. For example, a swing check valve may be sufficient for your needs instead of a lift check valve.

Conclusion

The cost of a new check valve can be significant, but it is important to remember that it is a critical component in many industrial processes. While there are ways to reduce the cost, it is important to prioritize quality and reliability. By considering the factors that affect the cost of a new check valve and shopping around for the best deal, you can find a check valve that meets your needs and budget.

Leave a Reply