6 inch butterfly valve is a type of valve that is commonly used in various industries, including chemical, water treatment, and HVAC. This article provides a comprehensive overview of 6 inch butterfly valve, including its characteristics, advantages, and applications. By the end of this article, readers will have a thorough understanding of the differences between 6 inch butterfly valve and other valves.

Introduction

6 inch butterfly valve is a type of valve that is used to regulate the flow of fluids in various industries. It is commonly used in chemical processing, water treatment, and HVAC applications. In this article, we will provide a comprehensive guide to 6 inch butterfly valve, including its characteristics, advantages, and applications.

Characteristics of 6 Inch Butterfly Valve

6 inch butterfly valve has several characteristics that make it an ideal valve for various applications. Some of the key characteristics include:

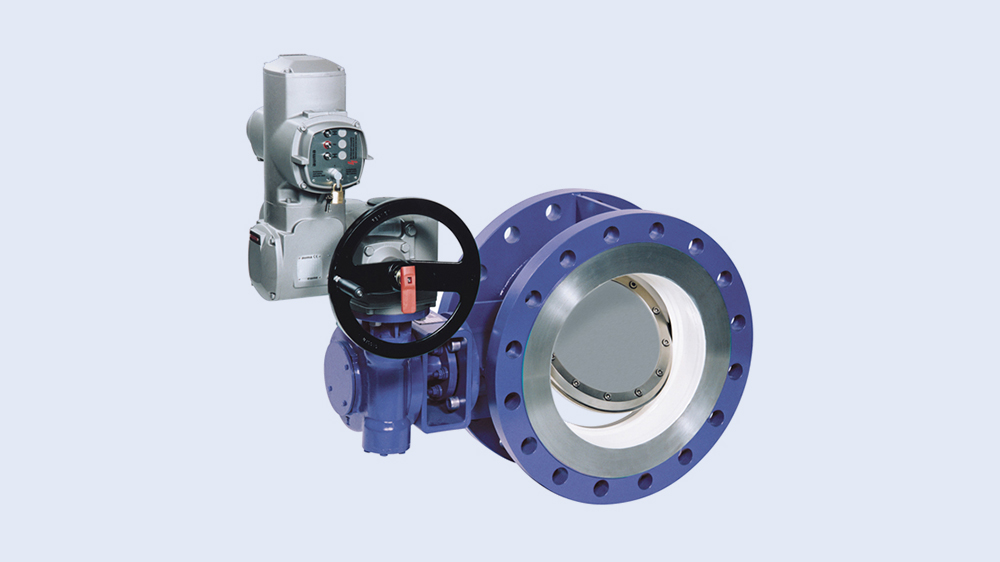

- Quick operation: 6 inch butterfly valve can be quickly opened or closed, making it ideal for applications where a quick shut-off is necessary.

- Low torque: 6 inch butterfly valve requires less torque to operate compared to other valves, making it easier to operate.

- Low cost: 6 inch butterfly valve is relatively inexpensive compared to other valves.

- Lightweight: 6 inch butterfly valve is lightweight, making it easy to install and maintain.

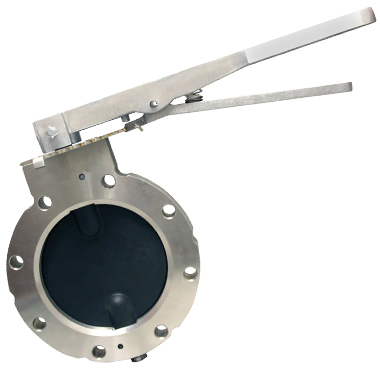

.jpg)

Advantages of 6-inch Butterfly Valve

6 inch butterfly valve has several advantages over other valves. Some of the key advantages include:

- Easy to install: 6 inch butterfly valve is easy to install due to its lightweight and compact design.

- Low maintenance: 6 inch butterfly valve requires minimal maintenance, reducing downtime and costs.

- Versatile: 6 inch butterfly valve can be used in a wide range of applications, including corrosive and abrasive environments.

Applications of 6 Inch Butterfly Valve

6 inch butterfly valve is used in various industries for different applications. Some of the common applications of 6 inch butterfly valve include:

- Chemical processing: for regulating the flow of chemicals in pipelines.

- Water treatment: for regulating the flow of water in treatment plants.

- HVAC: for regulating the flow of air in heating and cooling systems.

- Food and beverage: for regulating the flow of food and beverage products in processing plants.

- Pharmaceutical: for regulating the flow of pharmaceutical products in processing plants.

Examples

6 inch butterfly valve is used in various applications in different industries. For example, in the chemical processing industry, a 6-inch butterfly valve is used for regulating the flow of chemicals in pipelines. In the water treatment industry, 6 inch butterfly valve is used for regulating the flow of water in treatment plants.

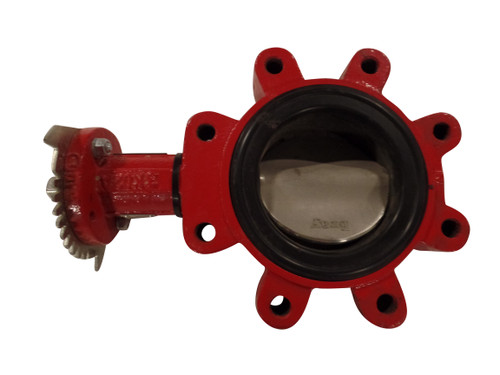

.jpg)

Conclusion

6 inch butterfly valve is a type of valve that is widely used in various industries for different applications. It has several advantages over other valves, including its ease of installation, low maintenance, and versatility. By understanding the characteristics, advantages, and applications of 6 inch butterfly valve, readers can make an informed decision about whether it is the right valve for their specific application.

.jpg)

-1024x805.png)

.jpg)