Discover the fundamental components that make up a gate valve, a crucial device in fluid control systems. This comprehensive guide highlights the key parts of a gate valve and their functions, from the body and bonnet to the gate and stem. Gain insights into the different types of gate valves and their specific applications across industries. Whether you’re an engineer or simply curious about valve mechanisms, this article provides valuable information to deepen your understanding of gate valves.

Introduction:

In fluid control systems, gate valves play a pivotal role in regulating the flow of liquids and gases. Understanding the various parts of a gate valve is essential for engineers and professionals in the field. This article serves as a comprehensive guide, exploring the functionality and significance of each component. From the body to the stem, we delve into the intricate design and applications of gate valves.

The Body: Foundation of a Gate Valve

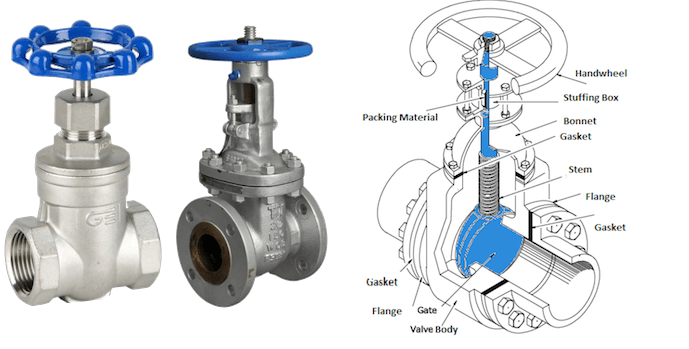

The body is the main casing of a gate valve, providing the structural integrity needed to withstand pressure and maintain fluid flow. Typically made of durable materials like cast iron or stainless steel, the body houses the other essential components and determines the valve’s overall strength and reliability.

Bonnet: Securing the Components

The bonnet acts as a cover, securing and sealing the internal components of the gate valve. It is attached to the body and ensures the stem and gate remain in position during operation. The bonnet is often threaded or bolted to the body, allowing for easy access to the internal parts for maintenance or repairs.

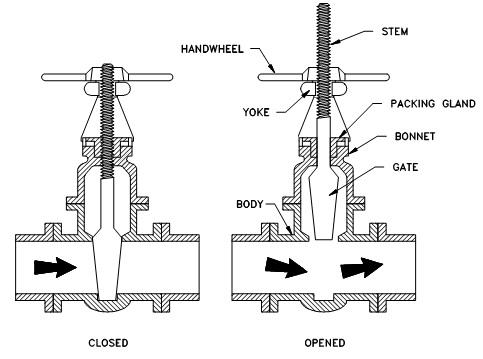

Gate: Controlling Fluid Flow

The gate is the centerpiece of the gate valve and serves as the controlling element for fluid flow. It moves up and down within the body’s passages to open or close the valve. When fully raised, the gate allows maximum flow, and when fully lowered, it restricts or stops the flow completely.

Stem: Connecting Handle and Gate

The stem connects the gate to the external handle or actuator. When the handle is turned or the actuator is activated, the stem moves the gate accordingly, regulating the fluid flow. The item must be strong and well-sealed to prevent leaks and ensure smooth operation.

Seat: Achieving a Proper Seal

The seat is the sealing surface located at the bottom of the gate valve’s body. When the gate is in the closed position, it makes contact with the seat, forming a tight seal that prevents fluid from leaking through the valve. The material of the seat varies depending on the fluid’s characteristics and operating conditions.

Types of Gate Valves and Applications

Gate valves come in various types, including rising stem, non-rising stem, wedge gate, and slab gate valves. Each type has its specific applications based on factors like pressure, temperature, and flow requirements. Rising stem valves are commonly used when a visual indication of the valve’s position is necessary, while non-rising stem valves are suitable for limited space applications.

Rising Stem vs. Non-Rising Stem:

A Comparison A rising stem valve has a stem that moves up and down visibly outside the bonnet when the valve is operated, providing a clear indication of the valve’s position. On the other hand, a non-rising stem valve’s stem is threaded into the gate, making it rotate without any external movement. The choice between these two types depends on the application’s specific needs and available space.

Conclusion:

Understanding the crucial parts of a gate valve is essential for professionals working in fluid control systems. From the body and bonnet to the gate and stem, each component plays a vital role in regulating fluid flow. The choice of valve type depends on the application’s requirements and environmental conditions. Armed with this comprehensive guide, engineers and industry experts can confidently optimize their fluid control systems with the right gate valve.

Leave a Reply