An eccentric butterfly valve is a type of valve that is used to control the flow of fluids in various industrial applications. It is a quarter-turn valve, meaning that it rotates 90 degrees to open or close the flow of fluid. The valve is designed with an eccentric shaft, which allows it to rotate freely and smoothly, providing a tight seal and minimizing the risk of leakage.

How Does an Eccentric Butterfly Valve Work?

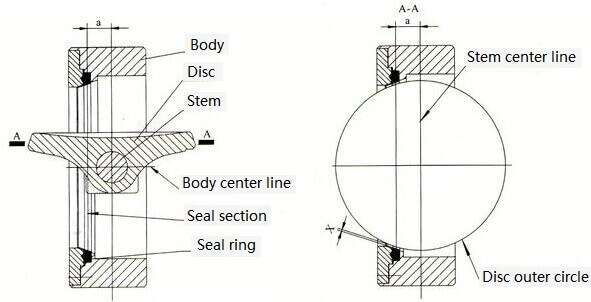

The eccentric butterfly valve consists of a valve body, a disc, and a shaft. The valve body is typically made of metal or plastic and has an elliptical hole in the center. The disc is mounted on the shaft and has a diameter that is slightly larger than the hole in the valve body. When the valve is opened, the disc rotates to align with the hole, allowing the fluid to flow through. When the valve is closed, the disc rotates to block the hole, preventing the fluid from flowing through.

Advantages of Eccentric Butterfly Valves

Eccentric butterfly valves have several advantages over other types of valves. One of the main benefits is their ability to handle high-pressure and high-temperature applications. They are also known for their reliability, durability, and low maintenance requirements. Additionally, eccentric butterfly valves are easy to operate and can be automated, making them ideal for remote or hard-to-reach locations.

Applications of Eccentric Butterfly Valves

Eccentric butterfly valves are widely used in various industries, including oil and gas, chemical processing, water treatment, and power generation. They are commonly used in applications such as pipeline valves, pump valves, and tank valves. They are also used in cryogenic applications, where the valve must be able to operate at very low temperatures.

Types of Eccentric Butterfly Valves

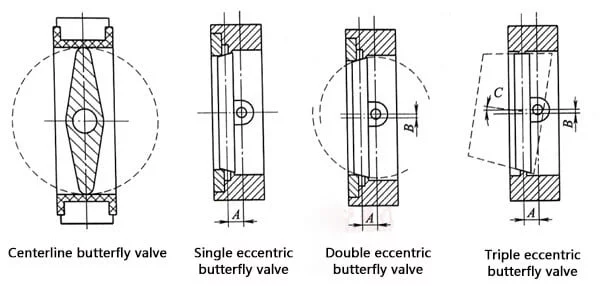

There are several types of eccentric butterfly valves available, including:

- Wafer-style eccentric butterfly valve: This is the most common type and is designed to be lightweight and compact.

- Lug-style eccentric butterfly valve: This type is designed for applications where a higher pressure rating is required.

- Flanged eccentric butterfly valve: This type is designed for applications where a flange connection is required.

Maintenance and Repair of Eccentric Butterfly Valves

Eccentric butterfly valves are relatively low maintenance, but they do require occasional repair and maintenance to ensure they continue to operate effectively. The valve disc and seat are the most wear-prone parts and may need to be replaced periodically. Regular cleaning and inspection of the valve are also important to prevent clogging and ensure proper operation.

Conclusion

In conclusion, eccentric butterfly valves are an essential component in various industrial applications. They are known for their reliability, durability, and low maintenance requirements, making them an ideal choice for remote or hard-to-reach locations. By understanding how they work and their advantages, you can make an informed decision when selecting a valve for your next project.

Leave a Reply