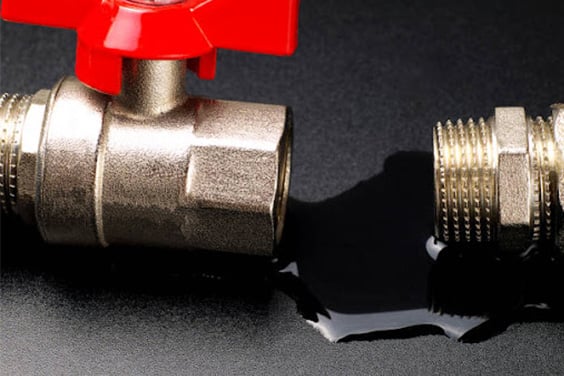

Ball valves are widely used in various industries, including oil and gas, chemical processing, and water treatment. However, ball valve shut off leaking is a common problem that can cause significant losses and safety hazards. In this article, we will discuss the causes and solutions for ball valve shut off leaking.

Causes of Ball Valve Shut Off Leaking

Ball valve shut off leaking can occur due to various reasons, including:

- Worn out or damaged valve seats: Over time, the valve seats can wear out or become damaged, causing the ball valve to leak.

- Incorrect installation: If the ball valve is not installed correctly, it may not seat properly, leading to leaking.

- Debris or contaminants: Debris or contaminants in the valve can prevent the ball valve from seating properly, causing leaking.

- Inadequate tightening: If the ball valve is not tightened adequately, it may leak.

- Corrosion: Corrosion of the valve components can cause leaking.

Solutions for Ball Valve Shut Off Leaking

To solve ball valve shut off leaking, the following solutions can be implemented:

- Replace damaged or worn out valve seats: If the valve seats are damaged or worn out, they should be replaced with new ones.

- Reinstall the ball valve: If the ball valve is not installed correctly, it should be reinstalled to ensure proper seating.

- Clean or replace the valve: If debris or contaminants are preventing the ball valve from seating properly, the valve should be cleaned or replaced.

- Tighten the ball valve adequately: The ball valve should be tightened adequately to prevent leaking.

- Use a ball valve with anti-leakage design: Some ball valves are designed with anti-leakage features, such as a lever or a spring, that can help prevent leaking.

Prevention of Ball Valve Shut Off Leaking

To prevent ball valve shut off leaking, the following measures can be taken:

- Regular maintenance: Regular maintenance of the ball valve should be carried out to ensure that it is in good working condition.

- Proper installation: The ball valve should be installed correctly to ensure proper seating.

- Use high-quality valves: High-quality ball valves are less likely to leak and are more durable.

- Avoid over-tightening: Over-tightening the ball valve can damage the valve and cause leaking.

- Monitor the valve: The valve should be monitored regularly to ensure that it is functioning properly and to detect any leaks early.

In conclusion, ball valve shut off leaking is a common problem that can cause significant losses and safety hazards. The causes of ball valve shut off leaking include worn out or damaged valve seats, incorrect installation, debris or contaminants, inadequate tightening, and corrosion.

The solutions for the ball valve shut off leaking include replacing damaged or worn out valve seats, reinstalling the ball valve, cleaning or replacing the valve, tightening the ball valve adequately, and using a ball valve with an anti-leakage design.

To prevent the ball valve from shutting off leaking, regular maintenance, proper installation, use of high-quality valves, avoiding over-tightening, and monitoring of the valve should be carried out. By implementing these measures, ball valve shut off leaking can be prevented, ensuring the safe and efficient operation of various industries.

Leave a Reply