In this article, we explore the features, applications, and benefits of a double offset butterfly valve. With its unique design and advanced functionality, the double offset butterfly valve is widely used for precise flow control in various industries. We delve into its working principle, highlighting its key features and advantages.

What is a Double Offset Butterfly Valve

A double offset butterfly valve is a versatile flow control device employed across multiple industries. This comprehensive article aims to provide an in-depth understanding of the features, applications, and benefits of the double offset butterfly valve.

By exploring its unique design and advanced functionality, we will highlight its significance in industries such as oil and gas, water treatment, and HVAC systems.

Features and Working Principle of Double Offset Butterfly Valve:

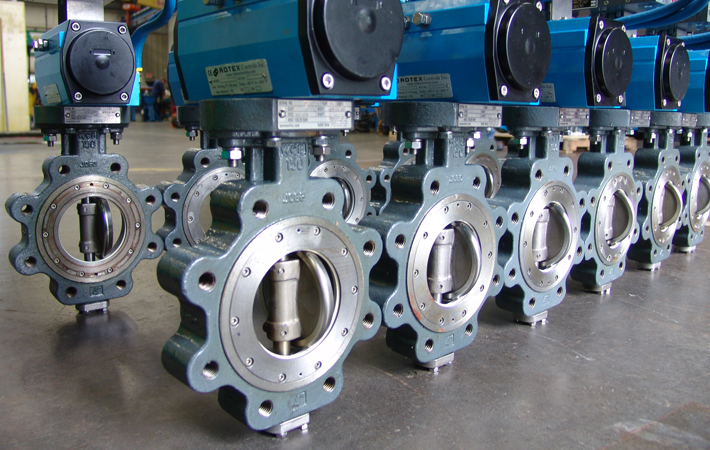

The double offset butterfly valve is designed to regulate and control fluid flow in pipelines. Its key features include a disc that rotates on a shaft, offset positioning of the shaft and disc centerline, and a butterfly-shaped sealing element. This design enables smooth and precise flow control by reducing friction and wear.

The offset shaft and disc centerline create an eccentric movement during operation, minimizing contact between the disc and the valve seat. This feature results in reduced operating torque, improved sealing performance, and extended valve life. The double offset design also provides a bubble-tight shut-off, ensuring zero leakage and enhancing process safety.

Applications and Benefits of Double Offset Butterfly Valve in Diverse Industries:

- Oil and Gas Industry: In the oil and gas sector, double offset butterfly valves are extensively used in pipelines, refineries, and storage facilities. Their robust construction, high-pressure capabilities, and excellent shut-off performance make them suitable for critical applications, such as oil and gas transportation, processing, and storage.

- Water Treatment and Distribution: Double offset butterfly valves play a crucial role in water treatment plants, ensuring efficient flow control in processes such as water distribution, sewage treatment, and desalination. Their quick operation, low torque requirements, and resilient sealing capabilities make them ideal for demanding water management applications.

- HVAC Systems: Double offset butterfly valves find widespread use in heating, ventilation, and air conditioning (HVAC) systems. They regulate the flow of air and various fluids, optimizing energy efficiency and maintaining comfortable indoor environments. The valves’ compact design, low weight, and reliable performance make them an ideal choice for HVAC applications.

Example:

For instance, in an HVAC system, a double offset butterfly valve is installed to control the flow of chilled water. The valve’s double offset design facilitates precise flow regulation, allowing for efficient cooling while minimizing energy consumption. Its bubble-tight shut-off ensures no leakage, maintaining optimal system performance and reducing operational costs.

Conclusion

In conclusion, the double offset butterfly valve offers superior flow control solutions in diverse industries. Its unique design, featuring an offset shaft and disc centerline, delivers efficient and precise flow regulation. With applications in the oil and gas industry, water treatment plants, and HVAC systems, the double offset butterfly valve ensures reliable performance, improved energy efficiency, and enhanced process safety.

Leave a Reply