From design and functionality to applications and advantages, this article provides a comprehensive comparison of globe valves vs. gate valves. Explore their unique features, benefits, and limitations, empowering you to make informed decisions when it comes to valve selection.

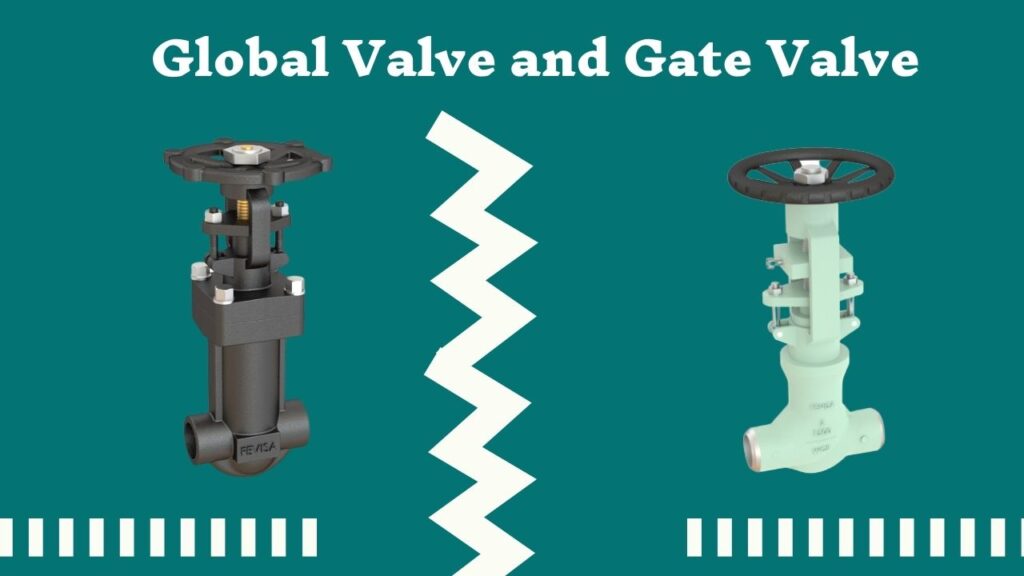

1. Introduction to Globe Valves and Gate Valves

Globe valves vs. gate valves are essential components used in controlling the flow of fluids in pipelines. While they serve similar purposes, each valve type possesses distinct characteristics that set them apart. Understanding these differences is vital for determining the most suitable valve for a particular application. Let’s delve into the dissimilarities between globe valves and gate valves.

2. Design and Functionality

2.1 Globe Valves

Globe valves have a spherical-shaped body with a movable disk or plug that regulates flow. They offer excellent throttling capabilities and can control fluid flow with precision. The flow direction in a globe valve changes as it passes through the valve body, resulting in increased resistance and pressure drop.

2.2 Gate Valves

Gate valves, on the other hand, feature a flat or wedge-shaped gate that moves up and down to control flow. They provide full flow capacity when fully open and minimal flow restriction when fully closed. Gate valves are primarily used for on/off applications and are known for their low-pressure drop characteristics.

3. Applications and Advantages

3.1 Globe Valves

Globe valves are commonly used in applications that require precise flow control, such as in the oil and gas industry, power plants, and chemical processing plants. Their throttling capabilities make them suitable for regulating flow rates and maintaining accurate control over fluid movement. Additionally, globe valves offer excellent sealing properties, minimizing the risk of leakage.

3.2 Gate Valves

Gate valves find extensive use in applications where the flow needs to be completely shut off or fully opened. They are widely employed in water treatment plants, irrigation systems, and wastewater management. Gate valves are advantageous for their simple design, low-pressure drop, and ability to handle high flow rates.

Conclusion

In summary, globe valves and gate valves are distinct types of valves with different designs, functionalities, and applications. Globe valves excel in precise flow control and are ideal for throttling purposes, while gate valves are preferred for on/off applications and high flow rates.

By understanding the differences between globe valves and gate valves, you can make informed decisions when selecting the appropriate valve for your specific needs. Consider the unique features, advantages, and limitations of each valve type, ensuring optimal performance and efficiency in your fluid control systems.

Leave a Reply