Explore the importance of this essential valve in preventing backflow and ensuring efficient flow control. Gain insights into different types of check valves and their unique features. Whether you are a professional in the field or simply curious about valve mechanisms, this article provides valuable information on the functionality and significance of check valves.

What Is a Check Valve?

A check valve, also known as a non-return valve or one-way valve, is a mechanical device designed to allow fluid flow in one direction while preventing backflow in the opposite direction. It ensures that liquid or gas flows in a specific direction, thereby maintaining system efficiency and preventing potential damage.

How Does a Check Valve Work?

A check valve operates on a simple principle: it opens to allow flow when the pressure on the inlet side is greater than the pressure on the outlet side, and it closes to prevent backflow when the pressure on the outlet side exceeds the inlet side. This automatic, self-acting mechanism ensures that the check valve functions effectively without the need for external control or power sources.

Types of Check Valves

There are various types of check valves, each designed to suit specific applications and operating conditions. Some common types include:

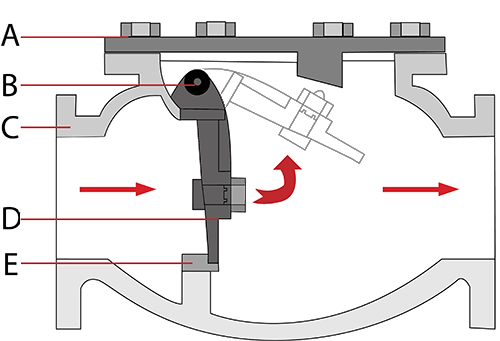

- Swing Check Valve: Utilizes a hinged disc to allow or block the flow.

- Ball Check Valve: Features a floating ball that rises to allow flow and drops to block backflow.

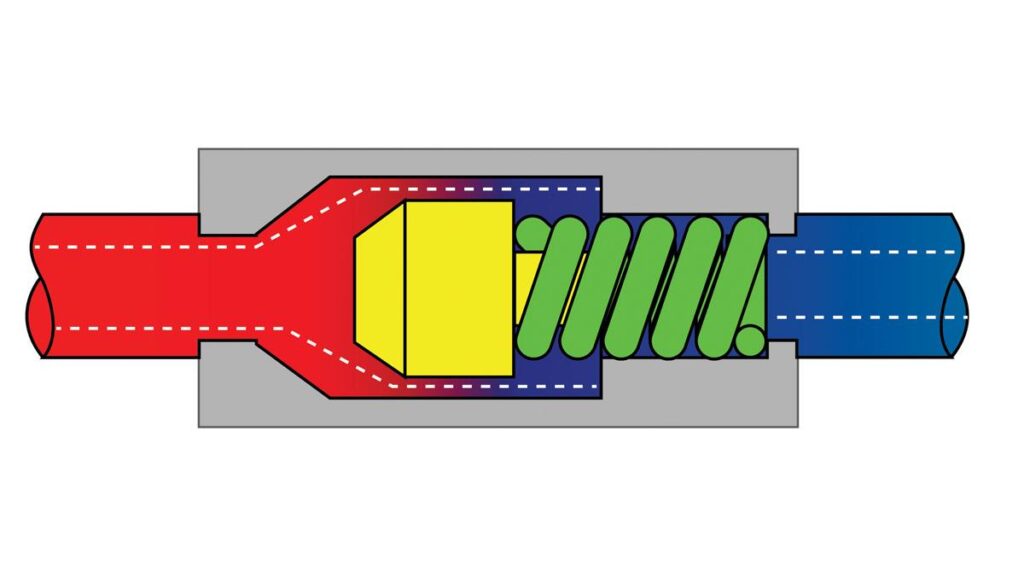

- Lift Check Valve: Utilizes a piston or disc that lifts to allow flow and settles to prevent reverse flow.

Applications of Check Valves

Check valves find extensive use across multiple industries and systems, including:

- Plumbing Systems: Prevents water backflow and maintains water supply integrity.

- Oil and Gas Industry: Ensures flow control and prevents backflow in pipelines and refineries.

- HVAC Systems: Controls the flow of air and refrigerants, optimizing system performance.

- Water Treatment Plants: Maintains one-way flow in water and wastewater treatment processes.

- Power Generation: Safeguards turbines from damage by preventing reverse fluid flow.

- Pharmaceutical and Food Processing: Maintains hygiene and prevents contamination in processing lines.

Conclusion:

In summary, check valves are essential components in fluid control systems. Their ability to allow flow in one direction while preventing backflow ensures system efficiency prevents damage, and enhances safety. By understanding the functionality and applications of check valves, professionals in various industries can make informed decisions regarding their selection and installation. Whether it is plumbing, oil and gas, HVAC, or other sectors, the appropriate check valve plays a vital role in maintaining smooth operations and optimizing fluid control.

Leave a Reply