Discover the inner workings of a butterfly valve and its wide range of applications. This comprehensive guide explores the functionality, design, and advantages of butterfly valves. By understanding how they operate and their various applications in industries such as HVAC, water treatment, and oil and gas, you can make informed decisions when selecting and utilizing butterfly valves for your specific needs.

How Does a Butterfly Valve Work

A butterfly valve operates on a simple yet effective principle. It consists of a disc or “butterfly” that rotates within a pipe to control the flow of fluids or gases. When the valve is fully open, the disc aligns with the pipe, allowing unobstructed flow. By rotating the disc, the flow can be gradually restricted or completely shut off. The disc’s position is controlled by a handle or actuator, providing precise control over the flow rate.

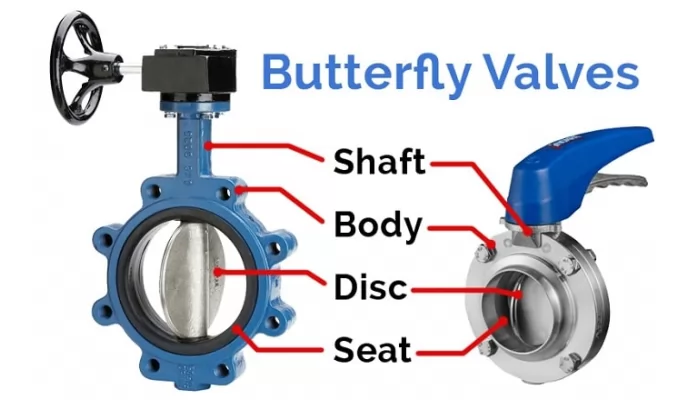

Design and Components of a Butterfly Valve

A butterfly valve comprises several key components. The disc, often made of metal or synthetic materials, is the central element that controls the flow. It is connected to a shaft that passes through the valve body. The valve body typically consists of a circular opening with flanges or grooves for easy installation. The handle or actuator, located on the shaft, allows manual or automated control of the disc’s position.

Operation of a Butterfly Valve

When a butterfly valve is in the fully open position, the disc is parallel to the flow direction, minimizing any flow resistance. As the disc rotates, it creates a variable degree of obstruction, regulating the flow rate. When the valve is completely closed, the disc forms a perpendicular barrier, stopping the flow entirely. The smooth, streamlined design of the disc and valve body reduces pressure drop and ensures efficient flow control.

Applications of Butterfly Valves

Butterfly valves find extensive applications across various industries due to their versatility and efficiency. In HVAC systems, they regulate the flow of air or water for temperature control. Water treatment plants utilize butterfly valves for controlling the flow of liquids, such as in pump stations and distribution networks. In the oil and gas industry, butterfly valves are used in pipelines and storage tanks to regulate the flow of crude oil, natural gas, and petroleum products.

Examples Highlighting Butterfly Valve Applications

-

HVAC Systems: A butterfly valve is installed in the ductwork of HVAC systems to control the flow of air in heating, ventilation, and air conditioning units. By adjusting the valve’s position, the flow rate and temperature can be regulated to maintain optimal comfort levels.

-

Water Treatment Plants: Butterfly valves play a vital role in water treatment processes. They are used to control the flow of water in pump stations, distribution networks, and treatment facilities, ensuring efficient and reliable water supply.

-

Oil and Gas Pipelines: In the oil and gas industry, butterfly valves are employed in pipelines to regulate the flow of crude oil, natural gas, and other petroleum products. Their ability to handle high flow rates and withstand harsh operating conditions makes them indispensable components in the industry.

Leave a Reply