Improve the performance of your vacuum system with a dependable vacuum gate valve. This article highlights the importance of this essential component and its benefits. From ensuring vacuum integrity to providing precise flow control, a high-quality vacuum gate valve offers enhanced efficiency and reliability. Find out how selecting the right valve can optimize your vacuum system’s performance and maximize productivity.

The Role of Vacuum Gate Valves in Vacuum Systems

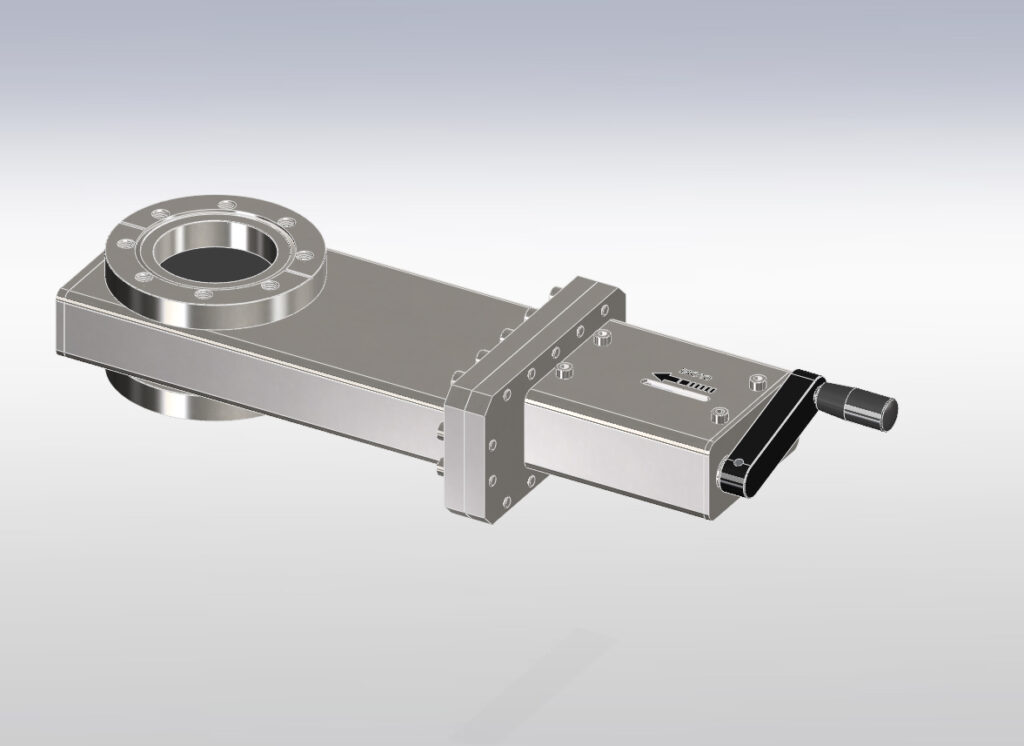

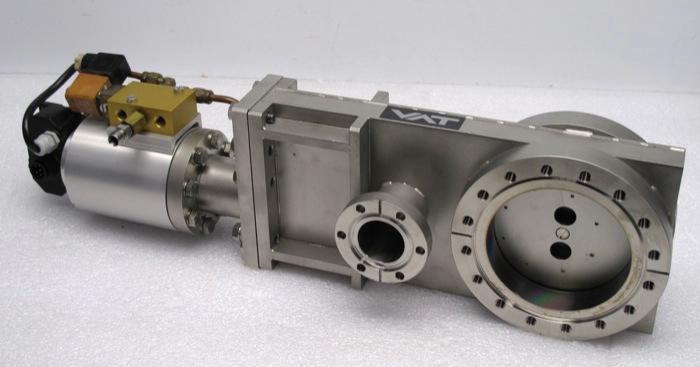

Vacuum gate valves play a crucial role in maintaining vacuum integrity and controlling the flow of gases or fluids within vacuum systems. These valves are designed to create a reliable seal, preventing air or contaminants from entering the system and compromising its performance. Additionally, vacuum gate valves enable precise control over the flow rate, allowing for efficient operation and process optimization.

Benefits of Utilizing a High-Quality Vacuum Gate Valve

Utilizing a high-quality vacuum gate valve offers several advantages. Firstly, it ensures precise operation and control, allowing for accurate adjustments of the flow rate within the vacuum system. Secondly, a reliable vacuum gate valve minimizes leakage, maintaining vacuum integrity and preventing performance issues. Moreover, these valves are designed to withstand the demands of vacuum environments, ensuring compatibility and long-term reliability.

Applications of Vacuum Gate Valves

Vacuum gate valves find applications in various industries and processes. In semiconductor manufacturing, they are used for wafer handling and vacuum chamber isolation. In research laboratories, vacuum gate valves play a crucial role in experimental setups and vacuum deposition systems. Additionally, they are utilized in the aerospace industry for space simulation chambers and satellite testing. These examples demonstrate the versatility and importance of vacuum gate valves in different fields.

Choosing the Right Vacuum Gate Valve

Selecting the appropriate vacuum gate valve for your specific application is vital. Consider factors such as the required vacuum level, flow rate, compatibility with gases or fluids, and the material of construction. Collaborating with a reputable supplier or manufacturer ensures access to expert guidance and a wide range of valve options to meet your unique requirements.

Real-World Examples

Numerous industries rely on vacuum gate valves to optimize their vacuum systems. In the semiconductor industry, these valves are critical for maintaining clean and controlled environments during wafer processing. In research and development, vacuum gate valves enable precise control over experimental conditions. These examples illustrate the practical applications and benefits of vacuum gate valves in real-world scenarios.

Conclusion

In conclusion, a reliable vacuum gate valve is essential for achieving optimal performance and efficiency in vacuum systems. By selecting a high-quality valve, you ensure precise control, minimal leakage, and compatibility with various vacuum environments. Partnering with a reputable supplier or manufacturer allows you to find the right vacuum gate valve for your specific application, enhancing the reliability and productivity of your vacuum system.

Leave a Reply