Enhance Control with a Pneumatic Gate Valve

Are you looking to improve control and efficiency in your industrial processes? A pneumatic gate valve can be the solution you need. This article will explore the benefits, working principles, applications, and tips for choosing and maintaining a pneumatic gate valve.

Understanding the Benefits of a Pneumatic Gate Valve

A pneumatic gate valve offers several advantages that contribute to its popularity in various industries. Firstly, its reliable operation ensures precise control over fluid flow. The valve opens and closes smoothly, allowing for accurate on/off control and eliminating the risk of leakage.

Additionally, a pneumatic gate valve exhibits versatility and can be used in a wide range of applications. It is suitable for handling various fluids, including liquids, gases, and powders, making it an essential component in different industries.

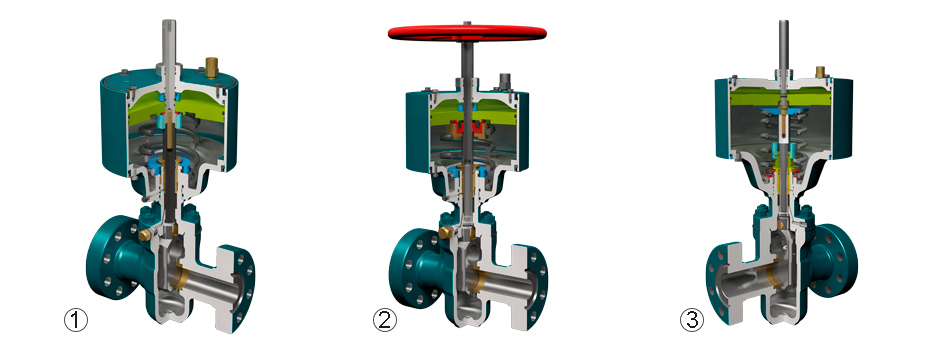

Working Principle of a Pneumatic Gate Valve

The pneumatic gate valve operates on a simple yet effective principle. It uses air pressure to control the movement of the gate mechanism. When air pressure is applied, the gate moves to open the valve and allow fluid flow. Releasing the pressure causes the gate to close, shutting off the flow.

The gate mechanism of the valve ensures efficient flow control by minimizing turbulence and pressure drop, resulting in improved process efficiency.

Applications of a Pneumatic Gate Valve

The pneumatic gate valve finds extensive use in the oil and gas industry for fluid control in pipelines, refineries, and offshore platforms. It provides reliable shut-off capabilities and precise control over the flow of oil, gas, and other hydrocarbons.

In chemical processing, the pneumatic gate valve is utilized for controlling the flow of various chemicals and fluids. Its ability to handle corrosive and abrasive substances makes it a suitable choice for maintaining process integrity and safety.

Choosing the Right Pneumatic Gate Valve

When selecting a pneumatic gate valve, consider the valve size and pressure rating to ensure compatibility with the system requirements. The valve should be capable of handling the fluid flow and pressure within the application.

Material selection is also crucial, as it determines the valve’s compatibility with the fluid and the process conditions. Choose materials that are resistant to corrosion, high temperatures, and chemical attacks.

Maintenance and Troubleshooting of a Pneumatic Gate Valve

Regular inspection and lubrication are essential to maintain the optimal performance of a pneumatic gate valve. Inspect the valve for any signs of wear, leakage, or damage, and lubricate the moving parts as recommended by the manufacturer.

In case of valve issues, diagnose the problem by examining the valve’s components and operation. Common issues include air leaks, gate sticking, or improper sealing. Troubleshoot and resolve these issues promptly to ensure the valve’s smooth operation.

Conclusion: Optimize Control with a Pneumatic Gate Valve

In conclusion, a pneumatic gate valve offers numerous benefits for enhancing control and efficiency in industrial processes. Its reliable operation, versatility, and precise flow control make it an essential component in various industries. By choosing the right valve, understanding the working principle, and conducting regular maintenance, you can optimize the control of your processes and achieve superior results.

Leave a Reply