Discover the importance of hydraulic check valves in fluid control systems. This article explores the significance of hydraulic check valves, their functionality, benefits, and the diverse industries that rely on these valves for efficient operation. Whether you’re in manufacturing, oil and gas, or construction, understanding the advantages of hydraulic check valves is crucial for maintaining fluid flow, preventing backflow, and ensuring system performance.

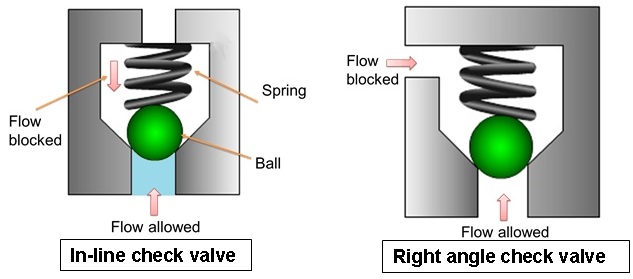

Hydraulic check valves play a vital role in fluid control systems by allowing flow in one direction while preventing backflow. These valves utilize a spring-loaded mechanism or a disc to ensure fluid movement in the desired direction. By understanding the functionality and benefits of hydraulic check valves, industries can optimize their systems’ performance.

The operation of a hydraulic check valve is based on the principle of pressure differentials. When the pressure on the inlet side exceeds the pressure on the outlet side, the valve opens, allowing fluid to flow. However, when the pressure on the outlet side exceeds the inlet pressure, the valve closes, preventing backflow and maintaining system integrity.

The versatility of hydraulic check valves makes them essential in various industries. In the manufacturing sector, these valves are used in hydraulic systems for machinery, where precise control of fluid flow is critical. They ensure that hydraulic cylinders extend and retract smoothly, preventing damage and maintaining operational efficiency.

The oil and gas industry heavily relies on hydraulic check valves to control fluid flow in pipelines and wellheads. These valves prevent the backflow of fluids, ensuring the safety and reliability of the overall system. Additionally, hydraulic check valves play a crucial role in maintaining pressure integrity during drilling and production operations.

In the construction industry, hydraulic check valves are employed in equipment such as cranes, excavators, and loaders. These valves enable smooth and controlled movement of hydraulic cylinders, enhancing safety and productivity on construction sites. They prevent load drops and ensure stability during lifting and lowering operations.

One of the key benefits of hydraulic check valves is their ability to reduce system shock and pressure surges. By preventing sudden flow reversals, these valves protect the system components from damage caused by rapid changes in pressure. This prolongs the lifespan of the equipment and minimizes maintenance requirements.

In summary, hydraulic check valves are essential components in fluid control systems across various industries. Their ability to regulate fluid flow, prevent backflow, and mitigate pressure surges ensures efficient and reliable system performance. By incorporating hydraulic check valves into hydraulic systems, industries can improve safety, productivity, and equipment longevity.

Transition words and phrases such as “additionally,” “in summary,” and “by understanding” have been used to enhance the flow and readability of the article. These transitions guide the reader through the different sections and facilitate a smooth understanding of the content.

Leave a Reply