We will talk about laser engraving machine carving three-dimensional objects with three axes of good or four-axis good, this topic, if you want to understand the friends, then when now follow the Shenzhen laser editor I go to see it.

Laser engraving machine in the carving plane product time, to use the three-axis and four-axis coupling to stop the common line, under the induction of the laser, three-axis and four-axis coupling at the same time to move, carved into shape, the goods carved into the goods that people want. The three and four axes are required to axis of the ability to move enough to stop carving.

Whether the three axes or four axes, there are really X-axis, Y-axis, Z-axis and rotation axis. It is a flat structure that exists, and the sculpture is also a flat figure. In the shape of the look similar. The so-called three axes, that is, in the reality of carving and processing, only three of the four axes are running, such as the x-axis, y-axis and rotation axis is running, then the Z-axis is stopped. And four-axis system, not constrained, four axes can run at the same time, all of it is a broader processing profile, of course, the price is also a little more expensive.

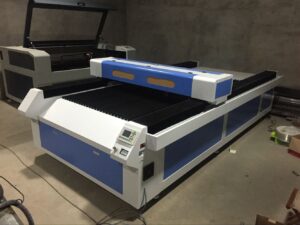

3 axis four-axis laser engraving machine

With the development of science and technology and the use of progress has been, three-axis and four-axis are able to stop carving, but from the perfect type and applicability of the four-axis is still used more.

Leave a Reply