Explore the important aspects of the 4 inch butterfly valve, including its size, functionality, and applications. This comprehensive guide provides insights into the benefits and uses of this valve, making it suitable for plumbing, HVAC, and industrial processes. Learn about the compact size and easy installation of the 4 inch butterfly valve. Discover its reliable flow control capabilities and versatility in handling various fluids. Whether it’s for commercial or industrial applications, this article offers valuable information for understanding and utilizing the 4 inch butterfly valve.

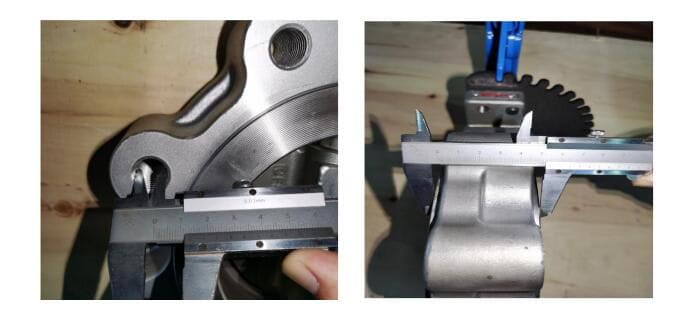

The Size and Dimensions of the 4 Inch Butterfly Valve

The 4 inch butterfly valve refers to its nominal pipe size, indicating compatibility with pipes that have a 4-inch inner diameter. This size is commonly used in plumbing, HVAC systems, and industrial applications. The compact design of the 4 inch butterfly valve allows for easy installation and efficient space utilization.

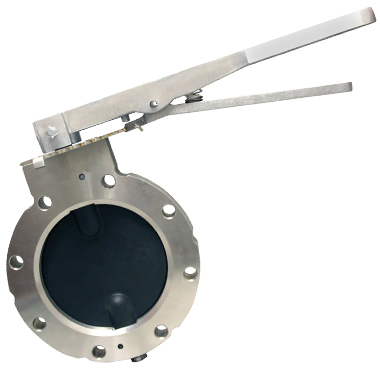

Functionality and Operation of the 4 Inch Butterfly Valve

The 4 inch butterfly valve operates by rotating a disc or “butterfly” within the valve body to control the flow of fluids. When the disc is parallel to the pipe, it allows maximum flow, while rotating it perpendicular to the pipe restricts or shuts off the flow. The quarter-turn movement of the disc enables quick and precise control over the flow rate, making the 4 inch butterfly valve suitable for both on/off and throttling applications.

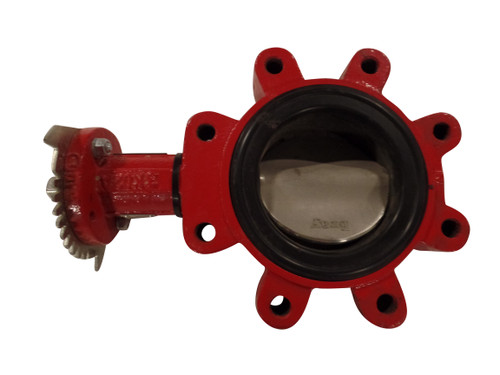

Applications of the 4 Inch Butterfly Valve

The 4 inch butterfly valve finds applications in various industries. In plumbing systems, it is used for water distribution, irrigation, and wastewater treatment. HVAC systems utilize these valves for regulating the flow of heating and cooling fluids. In industrial processes, the 4 inch butterfly valve is employed in chemical plants, power generation facilities, and oil and gas refineries. Its versatility, cost-effectiveness, and ease of maintenance make it a popular choice in these applications.

Example: 4 Inch Butterfly Valve in HVAC Systems

If you work in the HVAC industry, the 4 inch butterfly valve plays a crucial role in controlling the flow of heating and cooling fluids. These valves enable precise balancing of water flow in heating and chilled water systems, ensuring optimal performance and energy efficiency. With their compact size, the 4 inch butterfly valves can be easily integrated into HVAC systems, providing reliable flow control and minimizing pressure drop.

Conclusion

In conclusion, the 4 inch butterfly valve offers versatility, compact size, and efficient flow control capabilities for various applications. Whether it’s for plumbing, HVAC systems, or industrial processes, this valve provides reliable and precise control over fluid flow. Consider the specific requirements of your system and choose a high-quality 4 inch butterfly valve from reputable manufacturers to ensure optimal performance and longevity. With its ease of installation and operation, the 4 inch butterfly valve is an essential component for enhancing the efficiency and reliability of your systems.